Services

With existing skills & a one stop solution platform, we are able to cater to niche engineering sectors & provide engineering services and solutions for the domains listed below.

Engineering

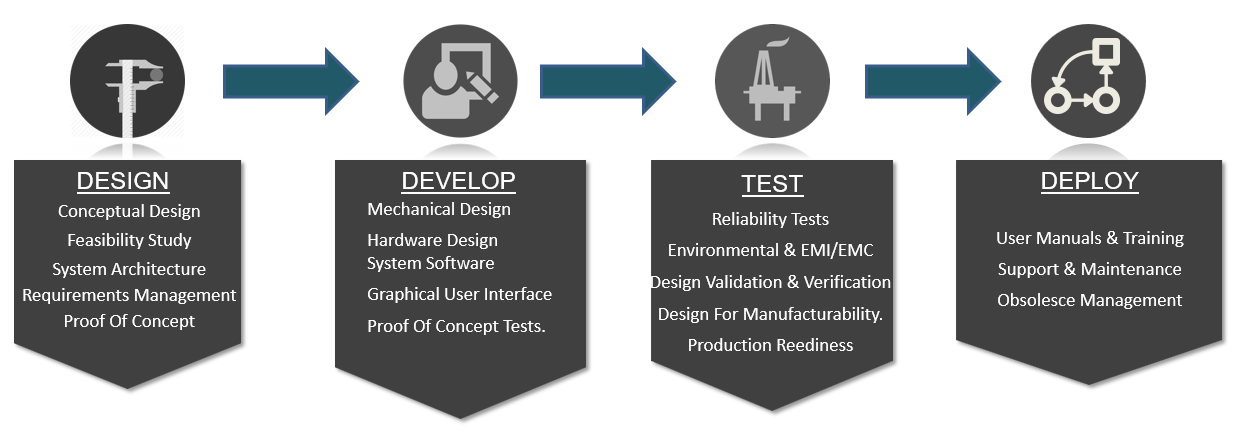

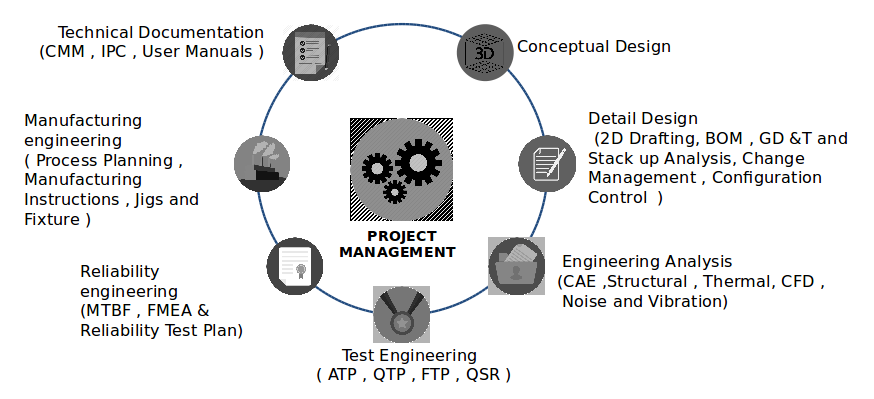

Flyvi offers comprehensive customized end to end system engineering solutions with reliability across industries.

Our system engineering involves from conceptual design thru design engineering, Manufacturing & Verification and Validation.

We believe Our systems engineering methodology helps to reduce the development cycle and brings products faster to market.

Flyvi offer end to end mechanical engineering services. With our expertise and proven track record in mechanical design and development, engineering analysis, verification and validation solutions and technical documentation for Aeropsace , Space , Defence and other Hitech industries.

Our electrical engineering services consist of electrical system engineering, Harness design, Electrical load analysis, prototype building, testing, and validations support. Our electrical design conforms to global standards such as IEC, IEEE, ANSI, UL, DIN, EN, MIL, and our team is having expertise with EMC/EMI.

- Electrical Schematic Harness

- Electro-Mechanical conversions

DRAFTING

- Elecrical load analysis

- Electrical layouts

- Power distribution

- Bonding and Grounding

- Electrical Harness

- Panel boards and switchboards

- Power control enclosures

- Relay panels

ELECTRICAL SYSTEM DESIGN

ELECTRO MECHANICAL SYSTEM DESIGN

Flyvi offer end to end Embedded and software engineering services in PCB design and development. With proven track record and capability in analog , digital and mixed signals , High speed board design , Microcontroller design , Digital signal Processing , FPGAs and Power electronics for aerospace and Defence industries.

- Field Programmable Gate arrays (FPGAs) Microprocessor based design

- Schematic Preparation , Component Selection

- BOM Optimization PCB Design and Gerber

- Multi layer PCB design ( +16 layers)

- Analysis: Thermal & Signal Integrity

- Testing of Boards

- Automatic Test Equipment (ATE) Design

- Develop applications, Middleware , Board Support Package(BSP)

- GUI based application for ATE design

- Embedded platforms including ARM ,MIPS, x86 controllers .

- Operating systems such as LINUX, Windows, Rots

- Software development in compliance with RTCA DO-178

- Functional and Endurance test

- Environmental tests as per requirement

- RTCA DO 254

- JSS 55555

- EMI / EMC Test : RTCA DO160 /

- MIL-STD- DO-461E

Hardware design

Software design

Test and Validation

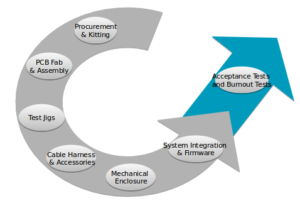

Manufacturing & Testing

We offer a full range of PCB assembly services, and specialize in the delivery of high quality, turn-key projects. We’ve developed a proven process to ensure that customers receive a quality product on time at a very competitive price.

At Flyvi , we follow industry standards for Electrostatic Discharge, IPC-A-610, and by carefully monitoring quality by routinely verifying assembly Instructions, Bill of Materials and IPC guidelines.

Flyvi offer full service PCB assembly and specializes in

- SMT surface mount assembly

- Through-hole assembly,

- Conformal coating

Flyvi provides a comprehensive range of full System Build and Integration solution from simple PCBA in to enclosure to complex chassis & wiring assemblies, final equipment manufacture and product encapsulation.

Flyvi engineering experts also participate with the customer in value engineering to further reduce product and manufacturing cost.

- Cost-effective end-to-end solutions

- Engineering Support

- Well-defined QA process

- Automatic Test Equipment's

- Provides Complete Traceability & C O C

Key Benefits

Flyvi provides a complete solution to mechanical manufacturing from high precision CNC Machining and Sheet metal fabrication for various materials including Aluminum , Stainless steel and Copper.